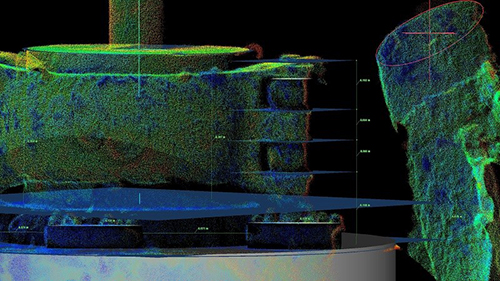

Horizon GmbH offers fast delivery of high-accuracy acoustic metrology using the latest LBL data acuisition and processing technologies in order to providing LBL Metrology services. Because of advantages such as flexibility, adaptability and online processing LBL is most commonly technique to provide many applications in the offshore survey services. With state-of-the-art LBL metrology technology, Horizon GmbH provides a complete production workflow to support the following fields of application (but not limited to):

– Spool pieces’ metrology

– Provision of ISO drawings

– High accuracy subsea installation and ROV tracking

– LBL Array Design and planning

– Provision of precise acoustic underwater positioning

Generally, LBL Acoustic Metrology is consisting of below items:

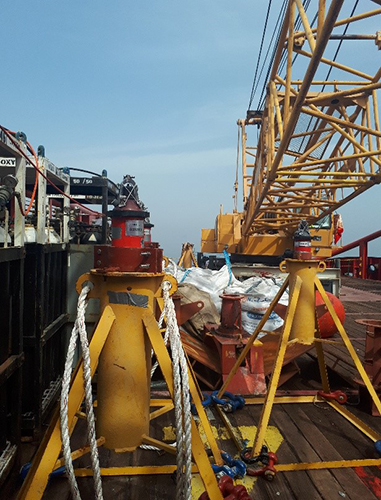

Fabricated bracket and tripod for deploying LBL Equipment

Nominated Metrology and Positioning equipment (e.g. fusion 6G)

Navigation and Monitoring equipment (main navigation and related navigation and positioning software)